There is no denying the fact that manufacturing businesses are among the many industries in which cybersecurity has emerged as a top priority. In 2021, a cyberattack affected approximately 90% of manufacturing organizations’ production or energy supply.

Improving operational technology (OT) network protection is trying, as it presents boundaries in various regions: operational (such as deciding which parts of the process the IT and OT teams own), technical (such as remote solutions), and investment (such as a lack of trained skills). However, industrial organizations are making progress in securing OT environments in the face of increasing digitalization by adhering to three fundamental principles:

• Enhancing Technological Foundation. Using the technology of today, businesses are securing OT environments with appropriate access and standardized controls.

•Allocating Responsibilities. A quick response to cyber incidents is made possible by establishing clear role responsibilities for the OT and IT teams, as well as external partners.

• Increasing risk awareness. Organizations can actively involve all stakeholders by using the appropriate incentives.

Effects of Cyberattacks on OT Environments

Because they can result in physical consequences (such as shutdowns, outages, leaks, and explosions), OT cyberattacks typically have higher and more negative effects than IT cyberattacks. Of 64 OT cyberattacks freely detailed in 2021 (an increment of 140% over the number revealed in 2020), around 35 percent had actual outcomes, and the assessed harms were $140 million for every incident.2 International dangers in 2022 brought about an 87 percent expansion in ransomware episodes, with 72% of the general rate increment over the 2021 figures coming from Europe and North America (40% more in North America, 32% more in Europe, and 28 percent more in different landmasses, contrasted and 2021 data).

Cyber attackers frequently use ransomware and less-got outsider associations with commandeering OT gadgets, an activity that can stop creation and operations.4 Modern associations normally face specialized and functional difficulties, including the accompanying, while attempting to safeguard against such assaults:

• Frameworks, which can be at least 30 years of age, with old weaknesses and restricted security controls (for instance, assailants can contaminate 2008 Windows servers utilizing an uncommonly created text style to execute noxious code)

• Restricted capacity to execute security controls on heritage OT gadgets provided before network protection turned into an issue and overseen by OEMs (for instance, sensors introduced on valves and associated with an organization without inward solidifying systems)

• Outsider far-off associations with control OT gadgets associated with an inward organization (for instance, assailants can strike a merchant-made organization and use it to contaminate different gadgets)

• Muddled possession among OT and IT groups that makes it challenging to concentrate, make due, and oversee OT digital tasks (for instance, reconciliation of assembling execution frameworks with big business asset arranging without the presentation of a 3.5 neutral territory).

• A lack of combined cybersecurity and automation skills with the required cybersecurity and automation-control-system-specific experience (for example, an expert in OT cybersecurity but lacking automation and process expertise)

• The ability of OT teams to patch devices and implement time-sensitive solutions is constrained by business, operational, and technical constraints that allow a continuous process to last up to three years before a planned shutdown (for instance, stopping an energy supply to update an operational server with a security patch).

• Risk tolerance versus risk awareness results in conflicting business priorities.

Factors Contributing To OT Cyber Security Success

A combination of technologies, procedures, and capabilities across an organization is required to improve OT cybersecurity in light of the difficulties. We were able to identify nine essential elements that revolve around three guiding principles to successfully enhance OT cybersecurity through our work with industrial organizations: increase cyber-aware capabilities and mindsets, ensure value-driven OT operations, and strengthen technological foundations.

To properly mitigate risks based on the criticality of assets, secure-by-design, implementation, and configuration for OT environments have standardized controls like the following:

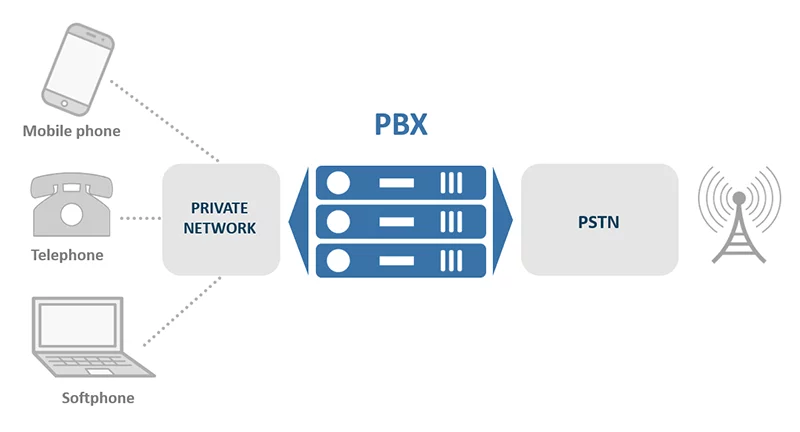

• Separation of OT networks from internal and external networks. The use of strictly configured security controls, such as firewalls, between the OT and IT networks and within the OT networks, as well as services like real-time data acquisition, remote support of OT networks, and integration between OT systems and ERP systems, all increase the need for secure convergence between the IT and OT environments through the implementation of security controls. Automation vendors should properly configure and validate security solutions.

• Cybersecurity controls and capabilities, threat detection, and assets. It is essential to have a clear understanding of the applications, vulnerabilities, and missing patches of the plant’s assets to assess their level of protection (for instance, by deploying threat detection solutions with OT asset management capabilities to establish a clear understanding of a plant’s cybersecurity posture). This is just as crucial as putting security measures and controls into the OT networks and systems.

• Security solution configuration. It is essential to implement security updates and controls. Notwithstanding, how well they are designed, made due, and regulated significantly impacts a compelling security control (for instance, inappropriate setup of a firewall could prompt trade-offs of the OT frameworks).

Leave a Reply