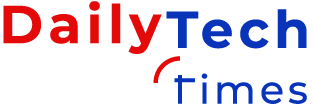

You need to have the appropriate tools for fused deposition modeling FDM if you are a 3D printer enthusiast or professional who is looking at bringing your projects to an advanced level. FDM is a widely used 3D printing technique in which thermoplastic filament melted and extruded layer by layer with the aim of creating three dimensional objects. You must have the right tools at your disposal if you want to optimize FDM printing.

In this article, we’re going to look at the essential tools for Fused Deposition Modeling and how they can help you achieve the best results.

Tools for Fused Deposition Modeling

Fused deposition modeling (FDM) is a popular 3D printing technique used by amateurs, students, and professionals. The right tools are essential to getting the best results. For anyone using FDM technology, we have compiled a list of ten key tools that should be considered to improve their experience with 3D printing.

1. Digital Caliper

Accuracy is crucial in 3D printing. A digital caliper is necessary to measure the dimensions of print parts accurately. It’ll ensure your prints match your digital design.

2. High-Quality

High-Quality Filament The quality of your prints can be seriously affected by the choice of filament. The materials covered are PLA, ABS, PETG, and TPU, each with different properties suitable for a given application. You should use the highest-quality filament to avoid problems such as clogged lines and unequal extrusion.

3. Removal Tool

Sometimes, it can be difficult to remove the finished prints from the printer bed. A good removal tool, such as a thin spatula or a palette knife, is essential for safely and effectively lifting prints without damaging them.

4. 3D Printing Slicer Software

The Slicer program converts 3D models into instructions that the printer can read. Tools such as Ultimaker Cura, PrusaSlicer, or Simplify3D offer advanced features for adjusting the height of layers, supporting, and printing speed.

5. 3D Printing Timelapse Camera

A timelapse camera, which can record the print process in order to be able to create visually appealing progress videos as well as help diagnose issues by reviewing footage so that you know exactly when and how it might fail, is also available.

6. Nozzle Cleaning

Needles Nozzles can become clogged with filament residues during printing. Finer-gauge needles are ideal for removing these blockages and ensuring an uninterrupted flow of filament.

7. Print the Adhesion Solution for your bed.

Using a bed adhesion solution is crucial to prevent warping and ensure first-layer adhesion. Blue painter’s tape, glue sticks, or specialized 3D printing adhesives are also available.

8. Cooling Fan

In the case of materials such as PLA, a cooling fan is necessary to quickly seal the filament after it has exited the nozzle, which helps to achieve better detail and overhang performance.

9. Post-Processing Tools

Postprocessing tools such as sandpaper, craft knife, and heat gun allow you to clean up, refine, or finish the print. The aesthetic and functional quality of the finished product can be significantly enhanced by these instruments.

10. A heated print bed.

A heating print bed is essential for printing with materials prone to warping, such as ABS. It keeps the first layer warm and reduces the likelihood of warping, ensuring more successful prints.

11. Filament Storage Solutions

Degradation due to environmental factors such as humidity and dust can be prevented by the proper storage solution for filament. A great option to maintain the quality of your filament is vacuumsealed containers with desiccants or specially designed storage compartments.

12. Enclosure

Enclosure Installing an enclosure around your FDM printer helps to maintain a consistent temperature during printing, particularly in the case of heat-sensitive materials. It also reduces noise and contains potentially harmful fumes.

13. Multimeter

For the troubleshooting and maintenance of the electronic components of your FDM printer, a multimeter is useful. In order to ensure the safe and proper operation of your printer, it can help you to check the correct voltage, continuity, and other electrical parameters.

14. Torque Wrench

For maintaining the mechanical components of your FDM printer, a torque wrench helps you tighten and adjust bolts and screws to the correct specifications, ensuring the printer frame remains stable and vibration-free during operation.

15. A temperature gun or infrared thermometer

A temperature gun provides a fast and accurate reading to ensure that the hot end and heating coil of your printer meet the correct temperatures, as set out in its settings. In particular, when experimenting with new materials or troubleshooting printing problems, this is of particular importance.

16. Ultrasonic Cleaner

An ultrasonic cleaner can effectively remove these supports without damaging the print, for users printing with filament that requires support structures such as PVA. To agitate the liquid, which is mostly water, and gently clean a printed object, they use High Frequency Sounds waves.

17. Software for Advanced Slicing and Simulation

More control of the print settings and customizations is provided by advanced slice software. Furthermore, prior to the printing of a document, software simulations may be able to predict possible problems with warping or deficiencies in structure.

18. Part Removal Mat

Without the use of excessive force or damage to the print bed, a rubber mat or a flexible magnetic plate may greatly facilitate the removal of prints from the build surface.

19. Filament Dryer

The properties of the filament may be significantly affected by moisture, resulting in poor quality prints. For filaments such as Nylon and PVA, filament dryers are necessary in order to ensure the drying of these fibers before optimum use.

20. Precision Tweezers

They are essential for the use of tiny parts, removal of excess filament from a print head or help with clearing nozzles. Precision tweezers have the ability to penetrate through narrow spaces and do not damage sensitive parts of a printing machine.

End Lines

The ability to print FDM 3D can be greatly enhanced by adding these additional tools into your toolkit. Each of the tools has a crucial role to play in guaranteeing successful, high quality printing by keeping optimal filament conditions preserved and periodically reviewing the print process. These tools are the support necessary to achieve excellent results in fused deposition modelling, regardless of whether you are dealing with complex projects or just want better print quality.

Remember, in order for a successful 3D printing to take place, you need the right tools. You can streamline the printing process, achieve accurate and higher quality prints while taking your projects to a whole new level through investment in basic tools for Fused Deposition Models.

So, what are you waiting for? Equip yourself with the right tools and unleash your creativity with FDM printing today!